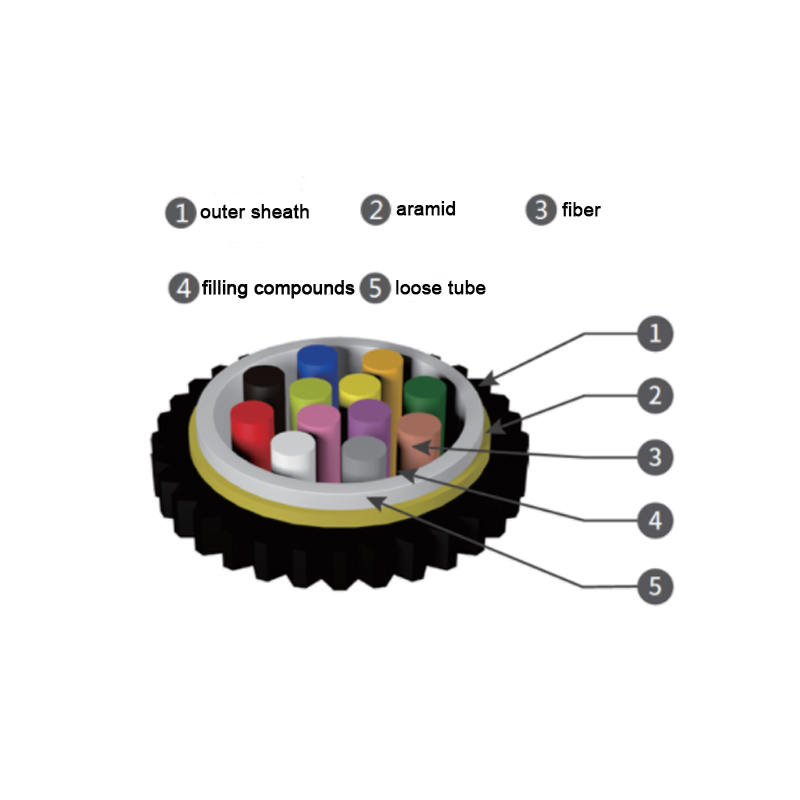

GCYFXTY Air Blown Cable is a loose tube made of a high modulus material with a 250µm single-mode or multi-mode fiber.

The tube is filled with a non-toxic and harmless waterproof compound, and the loose tube is twisted with a non-metallic reinforcing element. Then extruded black or colored high-density polyethylene (HDPE) sheath into cable.

With years of experience in blown fiber cable manufacturing, TUOLIMA has its own advantages in blown fiber cable. Welcome to sonsult us for more information about our blown fiber cable. As a professional fiber optic manufacturer, we also have different types of optical fibre for our customers. If you are interested, feel free to contact us.

Blown fiber optic cable is featured with small diameter, lightweight, low friction, excellent softness, and high fiber density, which can improve the laying efficiency and save construction cost.

SN | Item | Unit | Value |

1 | No. of fibers | count | 2/4/6/8/12 |

2 | Typical air blowing distance | m | ≥1000 |

3 | Storage temperature | ℃ | -20~+70 |

4 | Outer sheath thickness (nominal) | mm | 0.25 |

5 | Cable diameter (±5%) | mm | 2.5 |

6 | Cable weight (±10%) | kg/km | 4.5KGS/KM |

7 | Short term tension | N | 0.15G/0.5G |

8 | Short term crush | N/100mm | 150/45 |

9 | Micro ducts (OD/ID) | mm | 5/3.5 |

Note: Mechanical sizes are nominal values. G means the weight of the cable.

Characteristics of GCYFXTY Air Blown Fiber Optic Cable

Optical fiber characteristics (G.657A2 FIBER)

Mode field diameter (1310nm): | 8.6mm±0.4mm |

Mode field diameter (1550nm): | 9.6mm±0.5mm |

Cut off wavelength of cabled fiber (lcc): | £1260nm |

Attenuation at 1310nm: | £0.36dB/km |

Attenuation at 1550nm: | £0.22dB/km |

Bending loss at 1550nm (10 turns, 15mm radius): | £0.03dB |

Bending loss at 1625nm (10 turns, 15mm radius): | £0.1dB |

Bending loss at 1550nm (1 turns, 10mm radius): | £0.1dB |

Bending loss at 1625nm (1 turns, 10mm radius): | £0.2dB |

Dispersion in the range 1288 to 1339nm: | £3.5ps/ (nm•km) |

Dispersion at 1550nm: | |

Dispersion slope at zero dispersion wavelength: | £0.092ps/(nm^2•km) |

Specification of GCYFXTY Air Blown Fiber Optic Cable

1. Min. bending radius for installation

Static: 10*cable diameter

Dynamic: 20*cable diameter

2. Application temperature range of fiber optic cable

Operation: -5℃~ +60℃

Installation: -5℃~ +50℃

Storage/transportation: -20℃~ +70℃

Item | Test Method | Acceptance Condition |

Tensile Strength IEC 60794-1-2-E1 | Load: Short term tension Length of cable: about 50m Load time: 1min | - Fiber strain £ 0.25% - No fiber break and no sheath damage. |

Crush Test IEC 60794-1-2-E3 | Load: Short term crush Load time: 1min | - Loss change £ 0.1dB@1550nm - No fiber break and no sheath damage. |

Impact Test IEC 60794-1-2-E4 | Points of impact: 3 Times of per point: 1 Impact energy: 1J | - Loss change £ 0.1dB@1550nm - No fiber break and no sheath damage. |

Repeated Bending IEC 60794-1-2-E6 | Bending radius: 20 x OD or the minimum mandrel radius 75 mm No. of cycle: 25 | - Loss change £ 0.1dB@1550nm - No fiber break and no sheath damage. |

Torsion IEC 60794-1-2-E7 | Length: 1m Twist angle: ±90° No. of cycle: 10 | - Loss change £ 0.1dB@1550nm - No fiber break and no sheath damage. |

Cable bend IEC 60794-1-2-E11 | Diameter of mandrel:20 x OD Number of turns:4 Number of cycles:3 | - Loss change £ 0.1dB@1550nm - No fiber break and no sheath damage. |

Temperature Cycling IEC 60794-1-2-F1 | Temperature: -10oC~+60oC Time of each step: 12h Number of cycle: 2 | - Loss change £ 0.1dB/km@1550nm - No fiber break and no sheath damage. |

Packing material: Non-returnable wooden drum.

Both ends of cable are securely fastened to drum and sealed with a shrinkable cap to prevent ingress of moisture.

Cable printing: The sequential number of the cable length shall be marked on the outer sheath of the cable at an interval of 1meter ± 1%.

The following information shall be marked on the outer sheath of the cable at an interval of about 1 meter.

- Cable type and number of optical fiber

- Manufacturer name

- Month and Year of Manufacture

- Cable length

Drum marking: Each side of every wooden drum shall be permanently marked in a minimum of 2.5~3 cm high lettering with following:

- Manufacture name and logo

- Cable length

- Cable type and number of fibers

- Roll way

- Gross and net weight

Related Products